Yellow glass wool

Isolform purchases this glass wool in rolls, and

processes it by cutting it and bonding it to suitable materials.

Glass wool is industrially produced by melting a mix of glass

and sand at a temperature between 1,300 and 1,500 °C. This is

then transformed into fibres, and a special thermosetting resin

based binder is added, which increases the cohesion of the

fibres. The fibre is heated to about 200°C and calendered to

increase its mechanical resistance and stability. The glass wool

is then cut to make rolls or panels for action at high

pressures. |

|

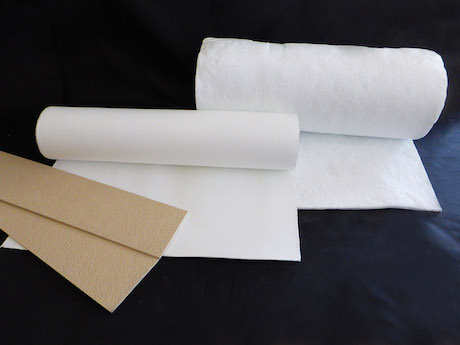

White glass wool

Isolform purchases this white glass wool in rolls,

and processes it by cutting it and bonding it to suitable

materials. This type of material is suitable for insulation

where significant temperature changes occur, and it can be used

with temperatures up to 400 °C. The production process is the

same as for the above glass wool, but in this case the material

is treated with a special phosphoric mineral binder, which

ensures compliance with the most stringent regulations on the

emission of formaldehyde. |

| |

|

|

Rock wool

Isolform purchases this rock wool

in rolls, and processes it by cutting it and bonding it to

suitable materials. The rock wool is obtained from diabase

igneous rock, basalt rock and dolomite rock with added

adhesives. In addition to being a natural material with

excellent thermal insulation properties, rock wool is also a

good sound proofing material. Rock wool does not absorb water or

humidity, and responds extremely well to fire: it does not

contribute to the development or the propagation of fire. |

|

Ceramic fibres

Isolform purchases ceramic fibre

in rolls, and processes it by cutting it and bonding it to

suitable materials. Ceramic fibre is a leading-edge technology

in the sector of insulating and refractory materials.

The main characteristics are extreme lightness, very low

coefficient of heat conductivity, limited heat absorption and

total insensitivity to thermal shock.

Fields of application: filling and stuffing for high

temperatures, insulating gaskets, insulation of twisted volumes,

boiler combustion chambers, special oven covering components,

thermal insulation for ladle covers, coating of industrial ovens

(roofs and walls), fire doors. |

| |

|

|

Glass fibre needled felt and padding

Isolform purchases these felts in roll, and processes

them by cutting them and bonding them to suitable materials.

These materials are made of non-organic "E" glass fibre, cut and

thermally stable, in compliance with DIN 1259.

Felted materials have good textile properties, excellent

resistance and mechanical stability.

They are soft, bulky, elastic, easy to perforate, cut and

handle. They can withstand operating temperatures up to

550°C/600°C.

They are suited to many different applications: Nautical and

shipbuilding, motorcycling and automotive sector, industrial

thermal and acoustic insulation. |

|

Rock wool needled felt and padding

Isolform purchases these felts in roll, and processes

them by cutting them and bonding them to suitable materials.

These products consists of long rock wool fibres, braided on

both sides, resulting in a compact felt. These products feature

stable dimensions and high heat resistance. They do not contain

adhesive resins, and can be used for sound and heat insulation

in the electrical appliance sector, thanks to their high

resistance to high temperatures and to being non-combustible.

They are particularly suitable for reaching or exceeding Class A

energy standards in the insulation of traditional or ventilated

electric or gas ovens. |

| |

|

|

|